Tougher Than Steel, Smarter Than Concrete.

Book Your Sample!

WHY CHOOSE SRK?

Cost That Cuts Competition

Access premium FRP products at unbeatable prices, getting a competitive edge and without compromising on quality and durability.

Quality Beyond Compare

A superior alternative offering exceptional strength with a high strength-to-weight ratio– ensuring top-notch quality, effortless installation and long-term reliability.

Corrosion? Never Heard of It

Opt for corrosion-resistant and long-lasting FRP solutions– engineered to endure the toughest industrial demands and harsh environments.

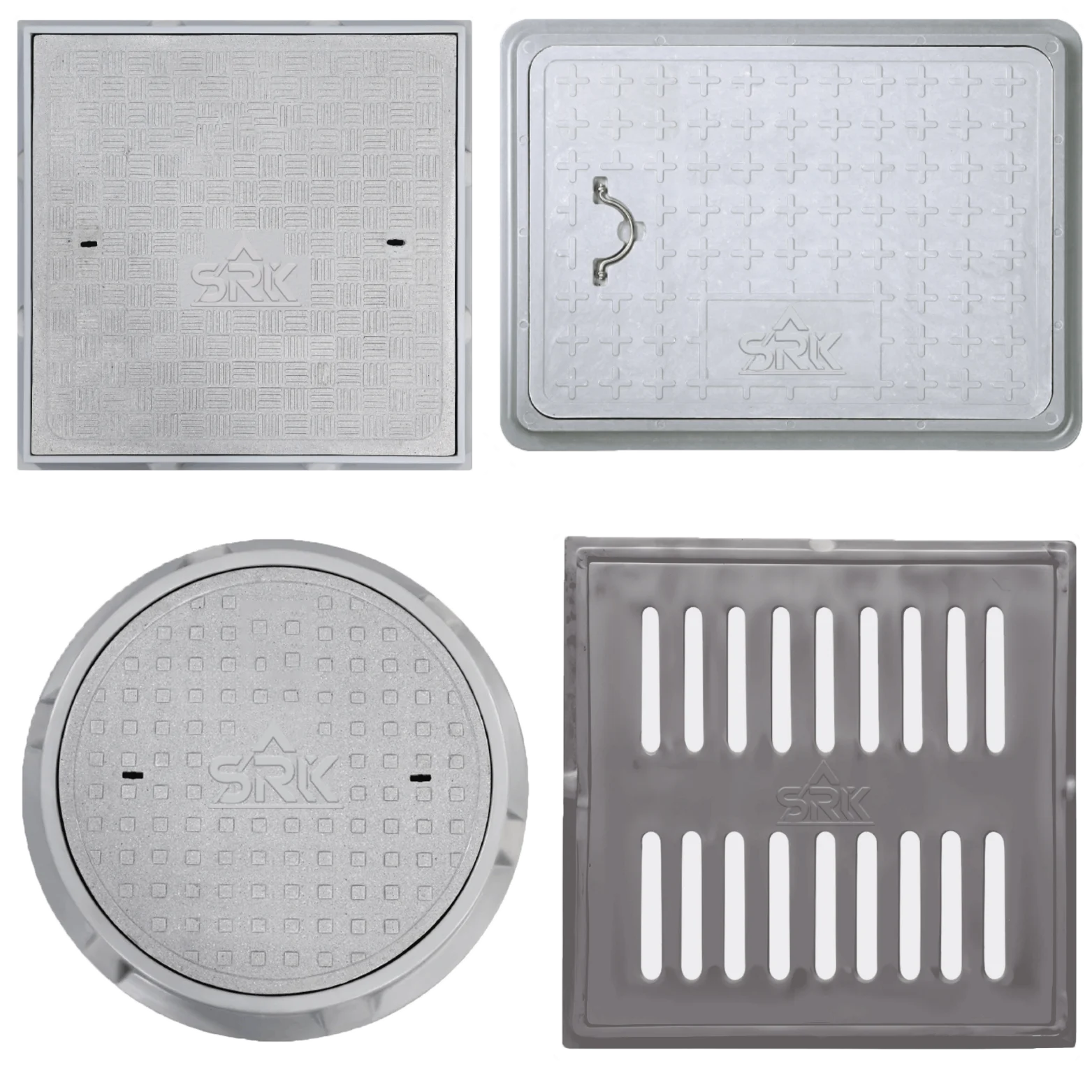

FRP Manhole

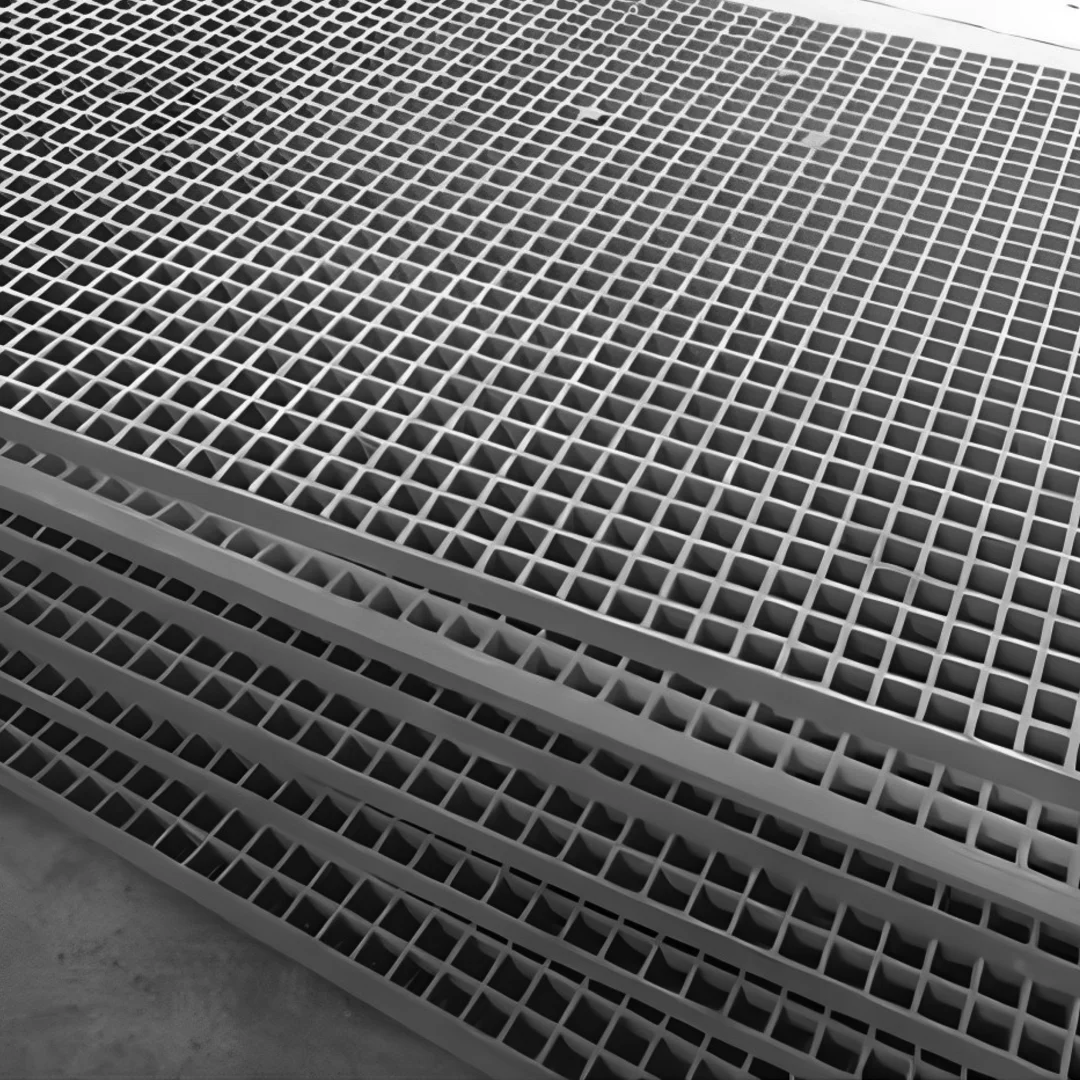

FRP Grating

FRP Ladder

ABOUT US

In today’s competitive industrial landscape, businesses are constantly seeking solutions that deliver strength, safety, and long-term reliability. At Shri Dhaniram impex, we are adamant towards giving personalized solutions and unparalleled experience for our partners. We leverage our exceptional quality products to provide you most reliable, sustainable and cost-effective materials even in most demanding environments. Our goal is to facilitate businesses build a safer and stronger future.

MANHOLE COVER

Feather Light Duty

Frame Size (in)

- 10x10

- 12x12

- 15x15

- 18x18

- 18x24

- 21x21

- 24x24

- 28x28

- 30x30

- 36x36

- 16 (dia)

- 28 (dia)

Capacity (Ton)

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

Heavy Duty

Frame Size (in)

- 12x12

- 18x18

- 24x18

- 24x24

- 36x30

- 36x36

- 36x36

- 36x36

Capacity (Ton)

- 5/12.5/25/40

- 5/12.5/25/40

- 5/12.5/25/40

- 5/12.5/25/40

- 5/12.5/25/40

- 5/12.5/25/40

- 5/12.5/25/40

- 5/12.5/25/40

Feather Light Duty

Frame Size (in)

- 10x10

- 12x12

- 15x15

- 18x18

- 18x24

- 21x21

- 24x24

- 28x28

- 30x30

- 36x36

- 16 (dia)

- 28 (dia)

Capacity (T)

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

- 5 Ton

Heavy Duty

Frame Size (in)

- 12x12

- 18x18

- 24x18

- 24x24

- 36x30

- 36x36

- 36x36

- 36x36

Capacity (T)

- 5/12.5/25

- 5/12.5/25

- 5/12.5/25

- 5/12.5/25

- 5/12.5/25

- 5/12.5/25

- 5/12.5/25

- 5/12.5/25

FRP (Fiber Reinforced Plastic) manholes are advanced, lightweight, and durable alternatives to traditional concrete, cast iron, or PVC manholes. They are designed to provide superior strength, corrosion resistance, and ease of installation. These manholes are widely used in sewage systems, drainage networks, telecom infrastructure, and industrial applications.

With a robust collection of manhole options ranging from medium duty application to heavy duty application, SRK manholes are 30–50% lighter than concrete or cast iron, making them easy to handle and install. Despite their lightweight nature, they offer high strength due to fiberglass reinforcement. They’re corrosion-resistant, leak-proof, and withstand harsh chemicals, gases, and UV exposure. With a non-conductive, maintenance-free design and a lifespan of 30–50 years, FRP manholes are ideal for sewage, industrial, electrical, and telecom applications.

Application

Airports

Telecommunications

Mall, Multiplex

Building Elevation

Highway & Ports

Railways

Advantages

UV Resistance

Non Corrosive

Electrical Work

High Strenght

Thieft Proof

Ease of handling

FRP manholes are available in a variety of designs to suit different applications and load demands:

Cylindrical FRP manholes

Cylindrical FRP manholes are widely used for underground drainage and sewage systems.

Square or rectangular manholes

Square or rectangular manholes are ideal for telecom and electrical infrastructure.

Modular FRP manholes

Modular FRP manholes offer customizable solutions tailored to specific project needs.

Traffic-load bearing manholes

For high-traffic areas like roads and highways, Traffic-load bearing manholes provide extra reinforcement.

Non-traffic manholes

Non-traffic manholes are lightweight options suited for parks, footpaths, and less demanding environments.

Myths vs Facts of FRP Manhole Cover

Myths

- More weight means stronger FRP

- More thickness means stronger FRP

- Use of FRP Rods increases the strength

- DMC means less strength

- LDPE/HPDE/PVC & FRP are same

- Rib pattern Provides better strength

Facts

- Strength of FRP is irrelevant to its weight. FRP’s strength depend on its material combination. FRP can provide strength of steel at fraction of steel’s weight

- Similar to weight thickness is also irrelevant to strength of FRP. Thickness can be increased by use auxiliary materials such as calcium, Sand etc. which lowers the strength of FRP

- Individually implanted rods don’t make any significant impact to strength. 40Ton load capacity FRP covers can be made without using rods

- Strength depends on Material combinations. And due to DMC there is Proper Pressure & temperate maintained to provide better Strength & Finish

-

All are different. FRP is strongest and most durable among them

- Rib means lower flow of the material during processing to ribbed parts. And also Ribbed patterns produces microcrack at corners to initiate early breakage.

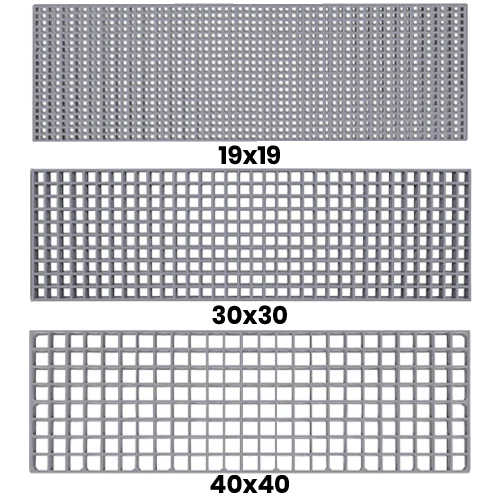

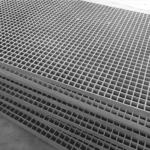

FRP GRATING

FRP Grating is a strong, durable, and corrosion-resistant alternative to traditional metal grating. It is made by combining glass fiber reinforcement with a polymer matrix (resin). It offers excellent mechanical properties, chemical resistance, and a long lifespan.

Catering to diverse application areas spanning from trench covers to walkways, elevation, wall facing, interiors, and beyond– FRP gratings are corrosion and chemical resistance, lightweight yet strong, non-conductive and fire-resistant, low maintenance and long life, slip-resistant surface

Application

Walkway/Walkpaths

Swimming Pool Area

Garden Ramps

Trench/ Drain Cover

Building Elevation

Basement parking

Fencing

Advantages

UV Resistance

Non Corrosive

Electrical Work

High Strenght

Thieft Proof

Ease of handling

Moulded FRP Grating

Moulded FRP Grating is made by layering fiberglass and resin in a mould, offering a uniform build and excellent corrosion resistance—ideal for offshore, chemical, and marine environments.

Pultruded FRP Grating

Pultruded FRP Grating is manufactured through a continuous process where fiberglass is pulled through resin. It offers higher strength than moulded grating, making it ideal for walkways, bridges, and heavy load-bearing applications.

Covered FRP Grating

Covered FRP Grating features an added solid surface layer that enhances load distribution and offers superior anti-slip properties. It’s especially suitable for pedestrian walkways and applications in the food industry.

Micro-Mesh FRP Grating

Micro-Mesh FRP Grating is designed with smaller openings to provide enhanced slip resistance, making it ideal for public spaces, stair treads, and offshore decks.

FIBERGLASS LADDER

Fiberglass ladders are essential tools, especially in industrial settings, to ensure smooth operations and facilitate tasks. Quality ladders are crucial for ensuring the safety and well-being of the concerned individual. SRK FRP ladders offer versatile solutions for both industrial and household applications.

SDI is a trusted FRP ladder manufacturer with deep industry expertise and provides a diverse range of FRP Insulated Fiberglass Ladders. SRK – A SDI Product adheres to international safety standards and delivers top-tier performance, leveraging features like 100% rust and waterproofing, UV stability, anti-slip gridding, flame retardancy, high strength-to-weight ratio, non-conductivity (safe for electrical use), and chemical resistance.

Application

Industrial & Household Repairs

Construction

Electrical Work

Industrial Maintainence

Extra Heavy Duty Industrial

Extra Heavy Duty Industrial

Heavy Duty Industrial

Medium Duty Commercial

Light Duty House Hold

Extra Heavy-Duty

Built for intense industrial tasks, these ladders can support heavy equipment and personnel with ease, ensuring maximum safety in demanding environments.

Heavy-Duty

Ideal for construction and industrial use, capable of handling consistent heavy workloads without compromising stability.

Medium-Duty

Suitable for maintenance work and regular operational tasks, offering a solid balance of strength and mobility.

Light-Duty

Perfect for light tasks in household or low-impact settings, ensuring convenience with adequate strength.

Download Our Brochures

WHY CHOOSE SRK FRP?

GLOBAL REACH

Got Questions? We've Got Answers.

Here’s everything you need to know about FRP, its benefits, and why it's the future of industrial solutions.

Fibre Reinforced Plastic/ Glass Fibre Reinforced Plastic is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually Fibreglass, Carbon, or Aramid, while the polymer is usually an Epoxy, Vinylester or Polyester Thermosetting Plastic.

Composite materials are made up of two or more materials on a macroscopic scale. Polymer matrix composites are plastics (resins) within which there are embedded fibres. The plastic is known as the matrix, and the fibres oriented within it are known as the reinforcement.

The reinforcement tends to be stiffer and stronger than the matrix providing stiffness and strength. Reinforcement is laid in a particular direction, within the matrix, so that the resulting material will have different properties in different directions, i.e., composites have anisotropic properties. This characteristic is exploited to optimize the design and provide high mechanical performance where it is needed.

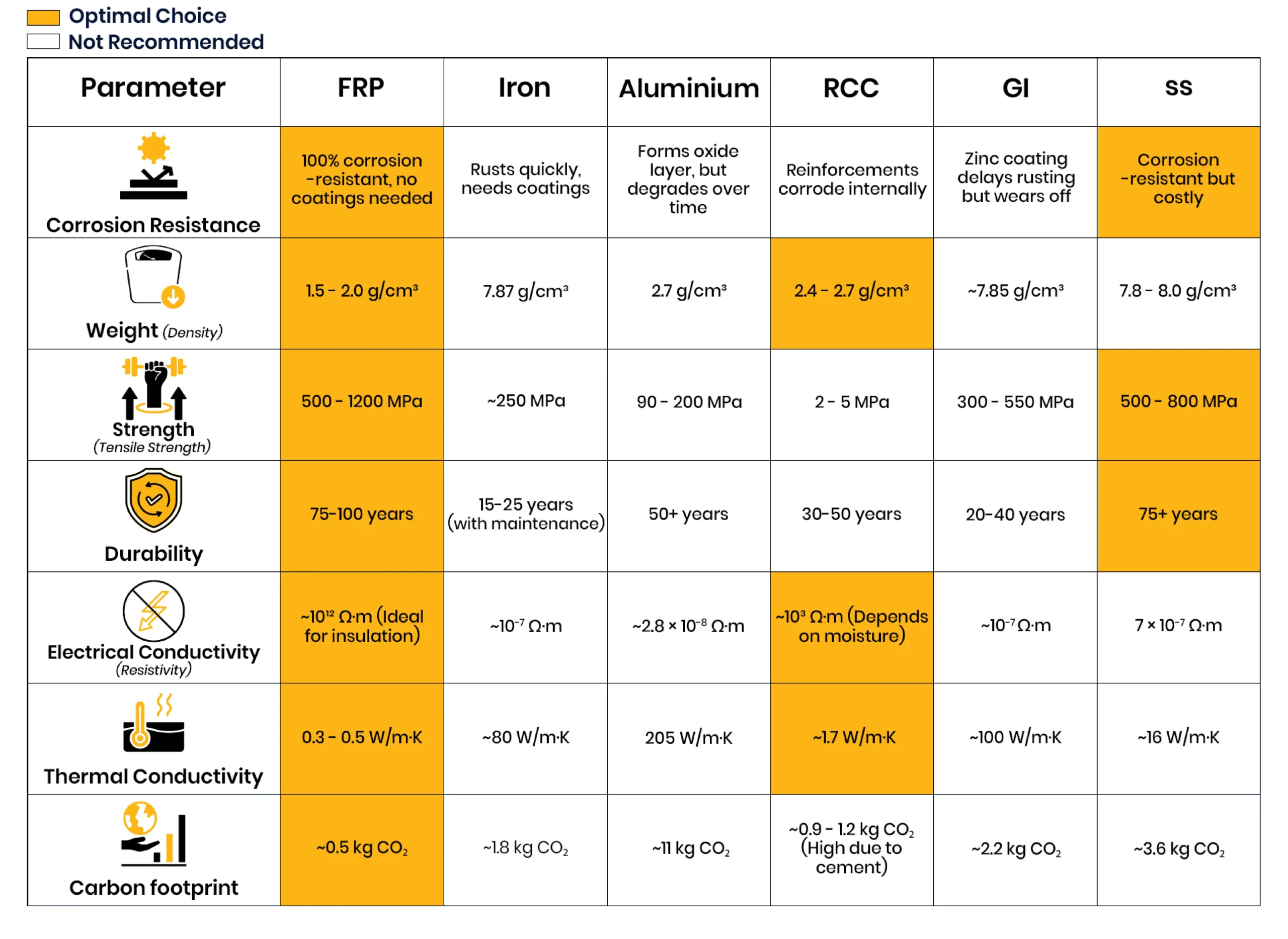

With extensive demands rising in the industrial landscape, the industry is getting more competitive than ever over the last few decades. It is becoming challenging to present a product that not only caters to our diverse needs and demands but also proves durability and stands firm against all challenges.

FRP, Fibre Reinforced Polymer, has proved to be the best discovery in civil engineering among concrete repair specialists, considering its reliability and efficiency over the long term. FRP reinforcement enhances infrastructure and provides multifaceted industrial solutions.

What are FRP products?

FRP is a superior alternative to traditional materials, composed of a polymer matrix reinforced with fibers made of carbon, aramid, or basalt. This reinforcement enhances the polymer’s properties, making FRP a powerful solution for modern applications. FRP materials effectively address issues like deterioration, daily wear, and the damages sustained by concrete buildings and metals.

Benefits of FRP materials

FRP encompasses all the qualities traditional structural materials lacked. Whether it's corrosion, rust, conductivity, UV degradation, or installation challenges, fiber reinforced polymer is the solution to all civil engineering problems.

With the extensive properties it upholds, there’s a wide array of industries adopting FRP, including aerospace, automotive, marine, and construction industries. FRP not only caters to diverse and exponentially increasing demands but also ensures optimum safety structures.

FRP delivers quality and durability with less cost, and ensures a high strength-to-weight ratio. It has an unmatched performance experience while offering unparalleled strength that steel or iron can't handle.

Different types of FRP products

SRK – A Shri Dhaniram Impex Product, offers you a range of FRP products fulfilling your industrial requirements. We are a Raipur-based FRP product manufacturer with hero products like FRP manholes and covers, FRP gratings, and FRP ladders, ensuring durability and reliability.

FRP Manholes and Covers

Delivering exceptional performance compared to cast iron, ductile iron, and RCC manhole covers, our diverse collection of FRP manholes and covers is truly a revolution in the industry, excelling in every parameter, whether it's strength, weight, conductivity, fabrication, or environmental impact.

Our selection of products is designed across both medium-duty and heavy-duty applications to meet the needs of the housing sector, municipal corporations, multiplexes, railways, telecommunications, airports, highways, ports, and much more.

FRP Gratings

An unprecedented result by combining a matrix of resin and fiberglass to create a material that has unmatched design and durability. Reduce maintenance costs and elevate aesthetics by choosing FRP gratings, which don’t corrode like steel.

SRK’s FRP Gratings are exceptionally superior to other traditional alternatives in every parameter, from life cycle cost and corrosion resistance to UV resistance, burglary-proof properties, ease of handling, and much more. Whether used as trench covers, walkways, elevations, stair treads, or interiors, FRP gratings outperform steel, aluminum, and timber thanks to their technical advantages.

FRP Ladders

Designed and built to challenge industry norms while ensuring compliance with national and international standards. Catering to extra heavy-duty industrial, heavy-duty industrial, medium-duty commercial, and light-duty household applications– while maintaining strict safety standards.

FRP ladders prove superior to traditional materials like metal, steel, wood, and others. They excel in non-conductivity, stability, and safety features like guard rails. This comprehensive range of products is tailored to meet specific industrial needs. SRK – A SDI Product, is dedicated to providing the best solutions to industrial challenges with their range of fiberglass ladders, setting new standards in durability, safety, and performance.

The civil engineering industrial diaspora is rapidly growing at a faster pace than ever before. The traditional practices of advanced composite components, however, fail to meet the exponential and structural demand of the sector. These traditional materials lead to high material and manufacturing costs while succumbing to corrosion, degradation, and limited durability.

The need of the hour calls for the adoption of new lightweight structural concepts globally, utilizing either all-FRP systems or new FRP/concrete composite systems. FRP strengthens the industry by reinforcing high strength-to-weight and stiffness-to-weight ratios, corrosion resistance, lightweight properties, and potentially greater durability than its conventional counterparts.

FRP won’t rust or corrode in wastewater and water treatment facilities. FRP endures severe weather challenges, offers durability and cost-effectiveness, and has proven to be the best component for pedestrian bridges, cooling towers, and military applications. Its anti-slip properties and strength make it ideal for the oil and gas industry, while its non-conductivity is advantageous in thermal and electric plants. It doesn’t stop here—the usage of FRP is never-ending, and industries eager for a better tomorrow and committed to providing the best are switching to Fibre Reinforced Polymer solutions.

Shri Dhaniram Impex

ALL-INDIA, EUROPE, MIDDLE-EAST, PAN ASIA, ETC.

Phone: +91 92018 38760

Book Your Sample!

A  Product

Product

Product

Product © Copyright SDI 2025. All rights reserved.